News

On the morning of March 15th, the 19th China Semiconductor Packaging, Testing Technology, and Market Annual Conference opened in Jiangyin. With the theme of "Innovation Leads, Collaboration Wins, and Building the Chip-to-End Product Manufacturing Industry Chain Together," this year's conference focused on industry hot topics for discussion.

Affected by the epidemic, this conference has undergone many twists and turns and was ultimately held in a combination of online and offline formats, attracting more than 42,000 views online.

Zhang Jianxin, Director and Deputy General Manager of GL Tech Co., Ltd., represented the company and ADT to attend the conference and gave a keynote speech on the application of step cutting technology in wettable flank QFN products.

In the back-end production process of wettable flank QFN products and various wafer-level packaging (WLP) modules, the step cutting and separation process is a critical step that directly affects product quality and yield.

Currently, the main processing method is to use diamond grinding wheels (Blades) to cut the product on a sawing machine to complete the separation. During this process, how to solve the problem of warpage and unevenness of the entire QFN or CSP product, how to ensure the accuracy of step cutting, how to avoid damaging the product in high-speed cutting, and how to guarantee cutting quality while maximizing UPH are some of the main technical challenges facing our IC packaging industry.

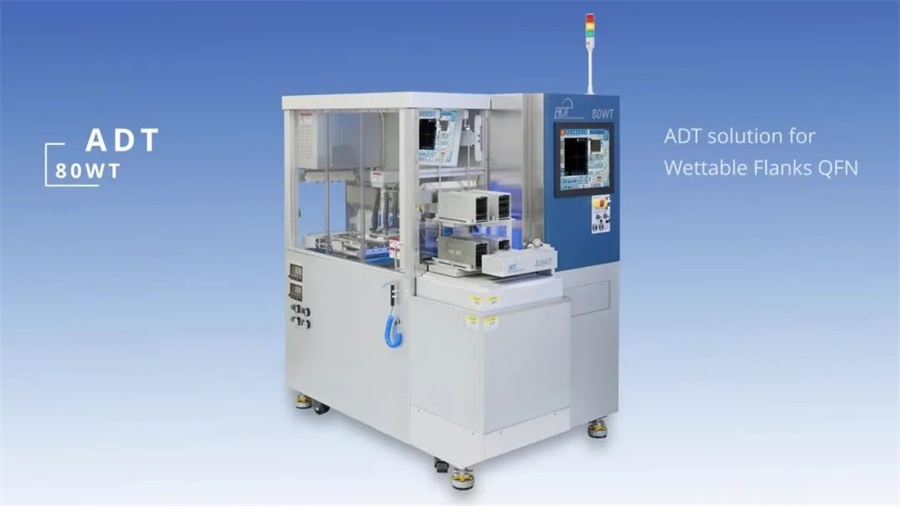

The latest dicing equipment developed and manufactured by ADT, the ADT 80WT, uses technologies such as Warpage Laser Scanning and Step Cutting Technology, and is equipped with several types of grinding wheel blades produced by ADT. It effectively soves the above technical problems and provides IC packaging enterprises with a comprehensive cutting technology solution.