Products

With a slower wear rate than Resin but faster than Nickel, Metal-bond (Sintered) blades are best suited for retaining package shape and size in applications such as: BGA, Soft Alumina, TiC, LTCC, Ferrite.

· Various substrates, suitable for various applications

· High-precision cutting

· Reduce wear and increase blade life

· Reduce overall purchase costs (CoO)

· High-precision blade dimensions

With a slower wear rate than Resin but faster than Nickel, Metal-bond (Sintered) blades are best suited for retaining package shape and size in applications such as: BGA, Soft Alumina, TiC, LTCC, Ferrite.

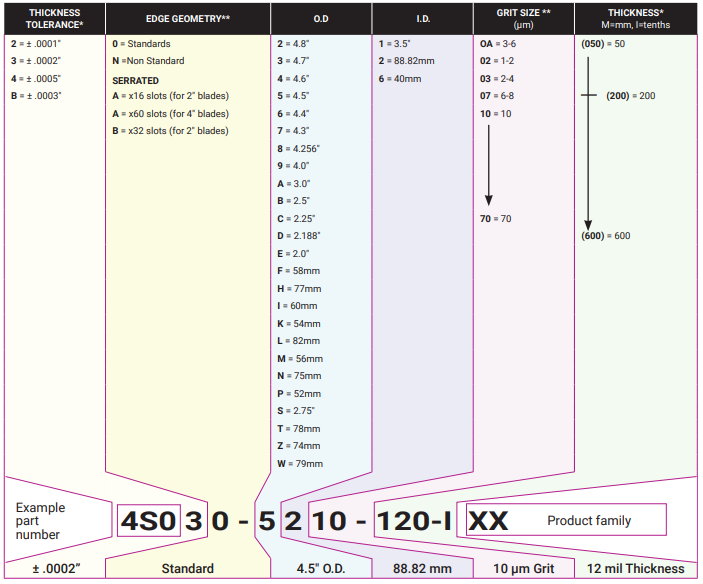

Blade thickness: 80 – 1500µm

Diamond grit size: 2 – 70 µm

Serrations:

Serrations available for sintered blades as well as various edge shapes

| Diamond grit size (µm) | Product | Material | Matrix |

| 45 up to 55 | BGA , LGA (Tape & Tape-less mounting method) | FR4, Plastic & molding | C2/R5 |

| 30 up to 50 | QFN ( Half Etched) | Cu leadframe + molding | Q7/C1 |

| 35 up to 45 | Passive & Active Devices. Communication Modules | LTCC | P1/P9 |

| 35 up to 45 | SAW Devices, RF Package | HTCC | P1 |

| 13 up to 25 | Camera Module | Glass/ IR Glass | P1/P5 |

| 25 up to 45 | Ceramic Packages | Alumina | P5/P9 |

Industry accumulation and succession

Core components · Autonomous control

Local research and development · Accumulate steadily